Solutions

Temporary or permanent protection tunnels

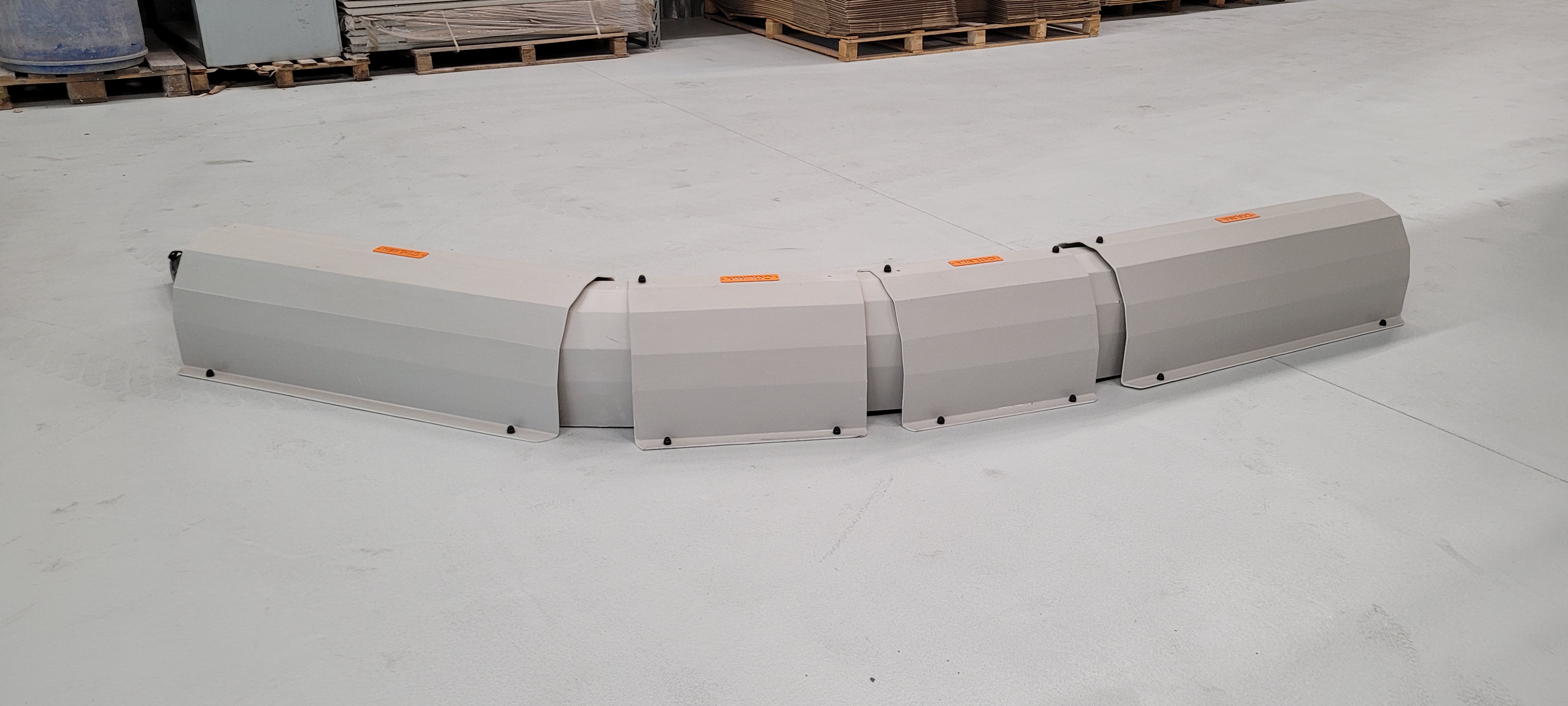

The composite protection tunnels for dry lines designed and manufactured by COMMET GROUP are very lightweight, making installation significantly easier and saving considerable time compared to heavy concrete tunnels that are cumbersome to handle.

They come in two versions:

1/ Temporary protection for the secure temporary securing of lines during work

2/ Permanent protection for the protection of lines fixed to the ground

Identified file

CNER/AE BCS 20,004 20,004 ind 2 Protection cowl

RST / RTE

Temporary solution: NORISKO No. A4340681 of January 5, 2007

PROTECTION TUNNELS FOR TEMPORARY LINES: IN A FEW WORDS

QUICK INSTALLATION

Easy Handling and Transport (6 kg/ml)

Easy installation with simple connections using cable ties for temporary solutions and ground connections for permanent ones

PERFORMANCE

Rotproof

Highly corrosion resistant

Neutral UV color

Density 1.7

PROTECTION

Confines projections

Protects individuals in case of cable breakdown

Protects the cable from falling objects

Description

Your site gets secured very quickly.

Made from fiberglass-reinforced layered composite and dope-dyed (gray for temporary installations, off-white for permanent installations),

COMMET GROUP protection tunnels are rotproof and have RTE approval.

The equipment is stackable for optimized storage.

The finish on the top surfaces features a "diamond point" nonslip texture.

How to choose?

The main criterion for choosing protection tunnels is based on the notion of temporary or permanent installation.

The temporary fixing mode does not require anchoring the cowls to the ground; a simple flexible link between the cowls will be sufficient.

The permanent fixing mode involves anchoring the cowls to the ground at four points using standard M12 anchor bolts, depending on the nature of the ground.

Permanent installations may require specific radii of curvature for the layout of the line.

Reference table

Realisations