Solutions

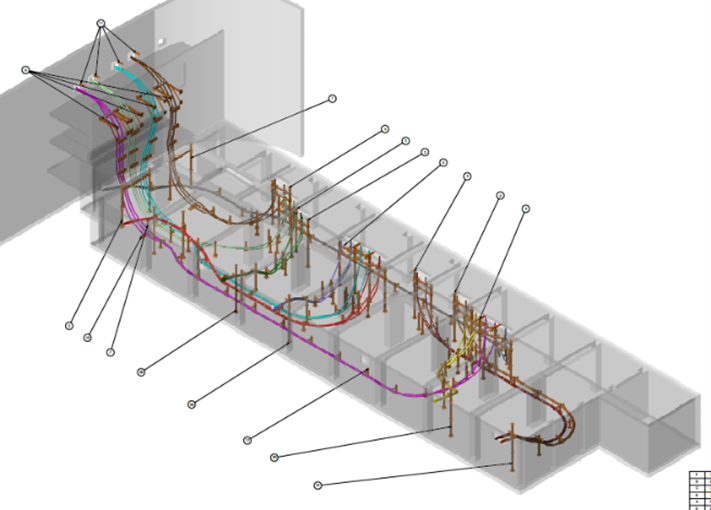

Installation study for lines and combs

COMMET Group has its own research department specializing in the design of solutions adapted to the original or real drawings after potential measurements we may have made on the work site in HTB cable tunnels, Gas Insulated Substations or Indoor Substations.

Our research department’s engineers and technicians integrate the requirements of the project as well as its setting up constraints, while complying to the RST recommendations established by the CNER (National Network Expertise Center) of RTE (French electricity transmission system operator).

Thanks to 3D views and VR (virtual reality) equipment, project teams can move in the digital environment and check every important technical aspect (pathways, interfaces, laying, etc.)

Installation study for lines and combs

Description

Each work site (gas insulated substation, indoor substation, tunnel) has its own technical constraints:

- Size and available room

- Traffic constraint

- Laying constraint

- Quantity and characteristics of lines (spacing between supports, linear mass, diameter, etc.)

- Combing constraints (radius of curvature, distance between elements, etc.)

- Access to the work site and characteristics (temperature, humid/submersible environment, etc.)

- Fireproofing requirements (anti-common mode, protection of HTA/HTB lines)

COMMET Group’s research department can take these constraints into account and conduct the necessary studies before defining and validation technically and economically possible solutions while complying with regulatory or specific requirements, as described by RTE:

- Study and combing drawing proposal

- Diagram of the installation with 3D view of the setup

- Complete drawing of the installations with the addition of COMMET products presented in the catalog

- Assembly process and digital simulation

Videos