Solutions

Fireproof anti common mode cowling

IVV Mineral Protect® screens

COMMET GROUP has developed an exclusive range anti common mode screens.

Patent pending

France No. FR1904086

Identified file

RTE/CNER AE-BCS-20-0004 of 01/02/21

IVV MINERAL PROTECT® ANTI-COMMON MODE SCREENS: IN A FEW WORDS

EXCLUSIVE PERFORMANCE

Fire-retardant and protective of other cables

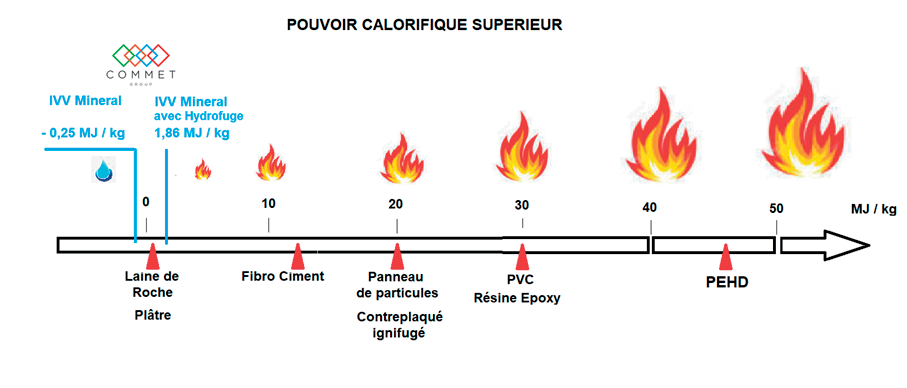

Negative GCV

QUICK INSTALLATION

NO LOCKOUT NEEDED

Light and easily installed system

MAXIMUM SECURITY

Total mechanical and dielectric protection

NATURAL FIBRES

Geometry adapted to multiple network configurations

WARNING

In humid or flooded environments, request version WP-PCS 30 MJ/kg

This version helps to increase the mechanical resistance of cowls in case they are underwater (water rising in tunnels) or in case of an extended exposure to higher humidity or to water flowing.

Description

Design to generally withstand flames and particularly when they are generated by an HTB cable breakdown or a peripheral fire in a technical room such as an HTB cable tunnel, screens have obtained the best possible grading in terms of reaction to fire according to the EN ISO 13501-6 Euroclass, with Aca (noncombustible), s1 (no smoke generation), d0 (no generation of flaming droplets); that is to say an M0 grading according to the NF P92-507 French standard.

These screens’ fire performance can entirely be compared to noncombustible materials like steel, rock, glass, concrete, plaster while being much lighter (< 5 kg/m2) and mechanically resistant to breakdowns.

Thanks to the use of 100% mineral materials, that are also non-conducting, and thanks to their geometry, the IVV MINERAL PROTECT® anti-common mode screens provide unprecedented mechanical and dielectric protection while allowing cables to dissipate heat energy with natural ventilation.

FOCUS ON THE IVV MINERAL PROTECT® TECHNOLOGY

PATENTED BY COMMET GROUP

Besides its capacity to slow down a high-voltage cable’s combustion, the IVV MINERAL PROTECT® material protects the other phases and other HTB underground lines in confined spaces such as underground tunnels. Developed by COMMET Group, the IVV MINERAL PROTECT® technology is the result of an environmentally friendly ecodesign process, as much in manufacturing processes as in the materials used: maximum decrease of the carbon footprint during production; no commonly used hydrocarbon-based resin; total recyclability of the 100% mineral materials used; and no use of products that could lead to the emission of hazardous gases, particularly in closed environments like tunnels.

The Gross Calorific Value (GCV) tests conducted in a COFRAC fire testing laboratory have shown that the IVV MINERAL PROTECT® technology benefit from better fire performance than noncombustible materials used in the construction of buildings.

SOLUTIONS THAT CAN BE ADAPTED TO BOTH TUNNELS AND RISERS

The COMMET GROUP range of IVV MINERAL PROTECT® screens can both be used in the linear parts of underground line tunnels as in more complicated parts at the entrance or exit of tunnels (trifurcation).

The variable or fixed size U-shaped cowls are generally more suitable for the ends of tunnels or in linear pathways with wall interruptions (ventilation rack, air shaft,...)

In the case of a tunnel entrance or exit with crossing cables or trifurcations, retractable cowls are available in COMMET’s catalog.

These can also be recommended for the protection of sensitive or hazard areas such as junction areas in tunnels.

AN INTERNAL RESEARCH DEPARTMENT

COMMET GROUP has an in-house engineering department at your disposal for the design of bespoke IVV MINERAL PROTECT® screens, according to your needs:

- Tilt in accordance with the wall’s verticality or with mounting brackets, centre distance

- Span, requested load

- Adaptation to existing equipment

- “L” or tablet shaped

- and so on

SNIFER: PREVENTING THE RISK OF FIRE

Preventing fire from spreading starts with reacting before it even ignites. Based on this observation, COMMET Group has developed a predictive technology that monitors the atmosphere around cables at the riser level under transformer substations. These areas are the most critical because they are located directly beneath the substations, making them highly exposed to the risk of fire ignition and rapid spread along the riser.

How to choose?

Depending on what elements need to be protected (between, near or at the intersection of lines, at pedestrian crossings) and on the environment (humid or not), contact us so that we can give you the appropriate solution.

In the case of existing installations, a simple measuring does not allow for the design of bespoke cowls that adapt to the configuration of lines that need to be protected. In that case, we will make a 3D scan of the area that needs protection in order to design the most adapted cowl, which will in turn be manufactured in our factories.

Models

L-SHAPED SCREEN OR PLATE

Adapted to linear parts of underground line tunnels and to more complex parts at the entrance or exit of tunnels (trifurcation).

Adjustable or fixed size

U-SHAPED SCREENS

Ideal for the ends of tunnels or in linear pathways with wall interruptions (ventilation rack, air shaft,...).

Adjustable or fixed size

BESPOKE SCREEN

Research, design and manufacturing by Commet Group according to your needs: span, load, tilt in accordance with the wall’s verticality or with mounting brackets, centre distance, adaptation to existing equipment...

JUNCTION PROTECTION COWL

COMMET GROUP’s anti-common mode solutions have also been developed to adapt to complex configurations, in small environments in terms of space and width.

Junction protection cowls are reinforced by high-resistance steel bars coated with the Copoprotec® protection.

This coating has dielectric isolation properties eliminating the need for grounding.

The use of composite materials for the manufacturing of cowls allows for a reduction of the parts’ weight, but also to create a mechanical protection without impairing electromagnetic fields around cables.

The cowls are designed so as to make assembly and maintenance easier if necessary.

PROTECTION OF CABLES BEHIND LADDERS

In some cases, access ladders to underground line tunnels are very close to cables.

COMMET GROUP has designed a range of cable protections to prevent operators from stepping directly on cables when the go up or down the ladders.

This mechanical protection made of composite, with a Copoprotec® structure, brings all the necessary resistance to support a person’s weight without deformation or punctures in case there is a residual protruding or sharp object under the safety footwear.

Videos

Realisations

.jpg&w=2048&q=75)